Blok's Draadvorm is best known for the bending of metal wire, but we do much more. As we offer many possibilities within the factory, we act as a one-stop-shop for many of our customers. The main advantages are: fast delivery times, transparent pricing, low transportation fees and full control over the quality from beginning to end.

Our processes

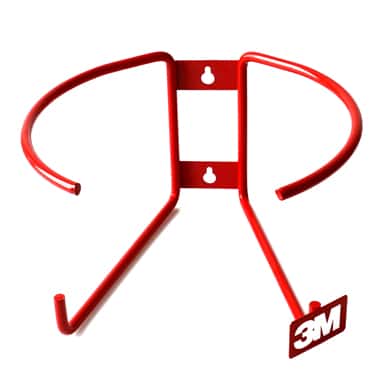

Bending

Our 0,3 to 14 mm metal wire products can be bent in 2D and 3D. We are continuously investing in our machines thus having the latest computer-controlled wire bending machines.

Welding

The welding and the assembly of wire products is done in our own factory. Plasma welding, MIG/MAG welding, TIG welding and medium frequency resistance welding are amongst the many possibilities.

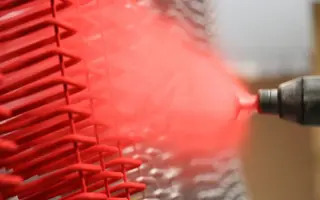

Powder coating

An epoxy, epoxy-polyester or polyester powder coating offers an excellent protection against corrosion. An alternative to this is PPA, a coating with a high impact resistance. We can offer you many possibilities in practically any RAL colour.

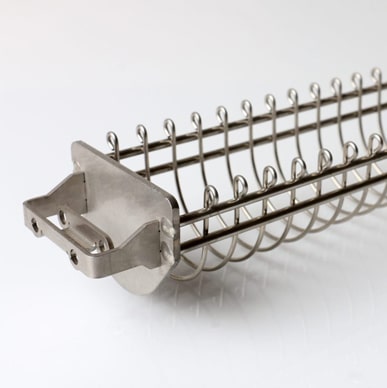

Stainless steel pickling

Restoring the composition of the welded materials and removing any potential weld discoloration. This prevents the material from oxidizing and provides a beautifully even finish.

Milling

Milling is a machining process in which material is removed by rotating the cutter. Our CNC-controlled milling machine is mainly used to make welding fixtures to an accuracy of 0,001 mm to create identical composite products.

Turning

Turning is a machining process in which the product rotates along one or more chisels and thus carries out the cutting operation. Our lathe is mainly used to make tooling for our machinery, making us flexible in the production process.

Pressing

The pressing of metal is done in our factory using our press break. Instead of bending all separate components, using this method we can bend the entire product by pressing it into the required shape in one go.

Planishing / cutting

Planishing and cutting are operations that are necessary for a number of our products, for example to manufacture protective grids or oven grills. Planishing and cutting is done in our factory using an eccentric press, with a force of up to 45 tons.