Our machinery

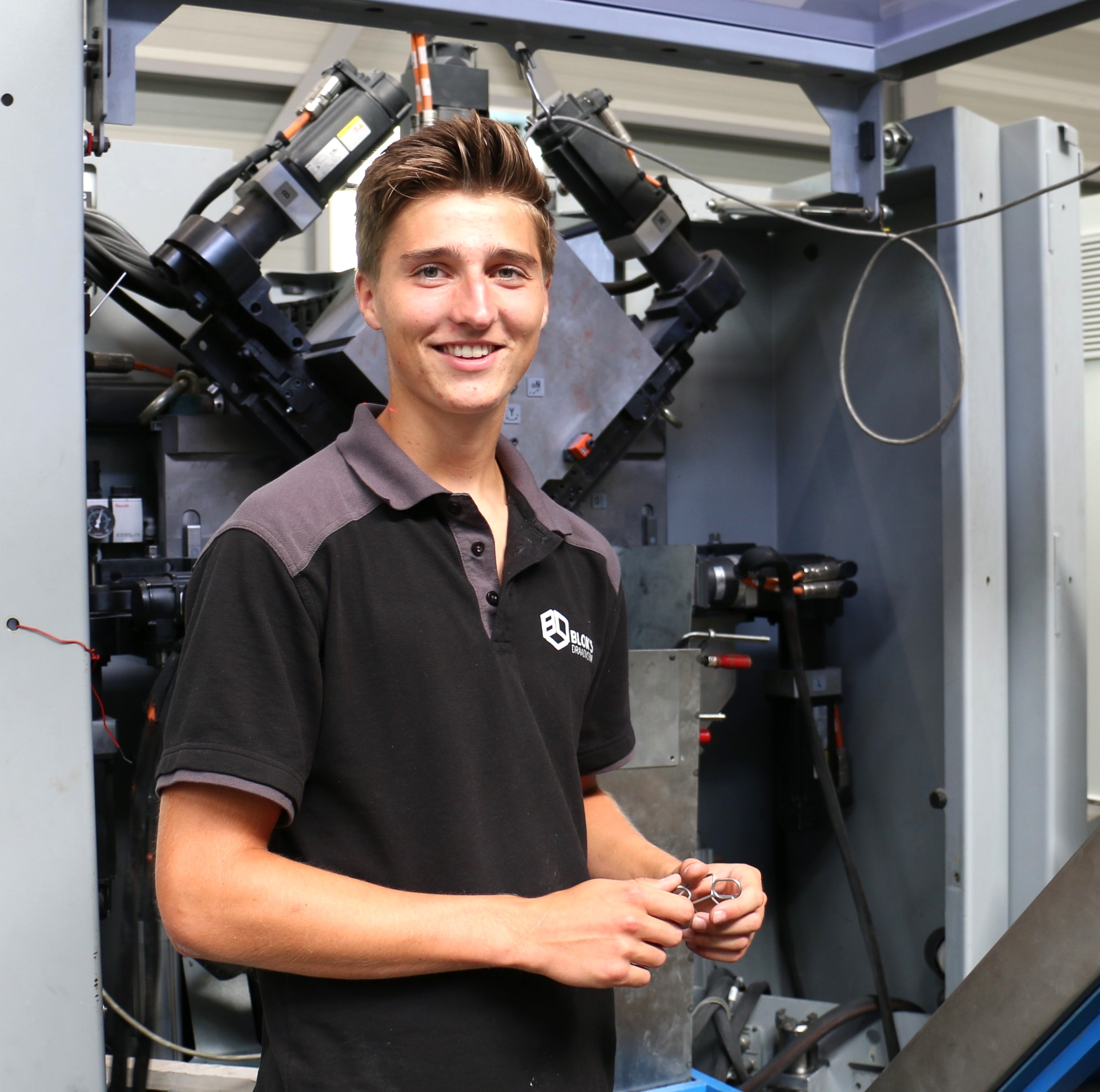

Wire bending machines

The wire diameters that our machines can bend spans from 0,3 mm up to 14 mm which enables us to manufacture almost any metal wire product, from tiny springs for blinds to parking systems for bicycles at train stations.

Welding machines and welding robots

At Blok's Draadvorm we weld by hand, with a machine or with robots. The welding techniques we use are plasma welding, MIG/MAG, TIG, (medium frequency) resistance welding.

Milling, turning and setting

In our tooling workshop we have a milling machine, a lathe and a press break. We use them to manufacture tools for our bending machines and fixtures for assembly of products such as fan guards for ventilating systems.