Sustainable and emission-free manufacturing

Our ambition is to completely produce emission-free. This has been taken into account during the construction of the new business premises in 2015. All building-related installations are carefully selected for energy consumption. In 2017 Blok’s Draadvorm took the next step and placed 700 solar panels on the factory roof.

THE GREAT BENEFITS

We bend and weld the metal wire products entirely on solar energy.

Our packaging system works according to a return exchange principle which results in no packaging costs.

The cleaning of products after pickling is done ultrasonically in a closed system so that no waste products are discharged into the sewer system.

The pre-treatment for powder coating (degreasing/phosphating) is done in a closed system in which the liquids are reused.

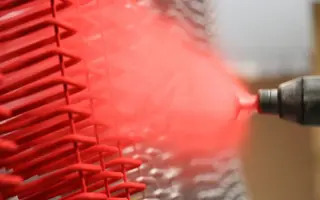

When powder coating, 99.5% of the unused powder is recovered through filter systems and reused.

All metal waste is remelted by recycling companies for reuse.